INTRODUCTION

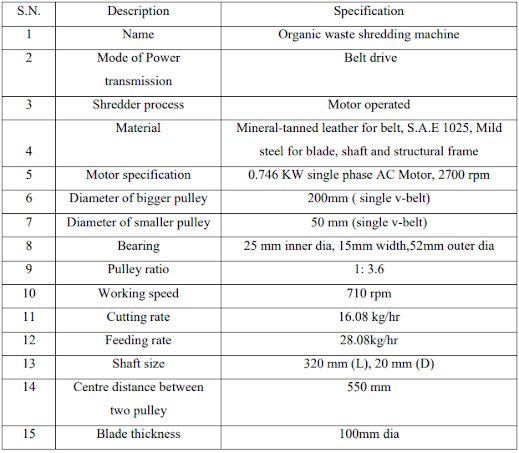

Waste management and disposal of the waste seems to be a major problem in developing countries where huge amount of waste has been generated due to enormous consumption. And after disposal of waste there lie an issue of size of the waste as the smaller size will have larger surface area so there will be more contact between bacterial environment and the waste particles for quick decomposition. So, this project will be helpful for designing and developing a shredder machine which would be a helping hand for organic waste management and recycling the waste into bio-gas and compost as a product.

What is Shredder?

Shredder is a machine or equipment which is used to reduce the size of the bulky material into fine particle for recycling or destroying purpose. Shredders can be of many types based on the material being processed.

Fig Motor operated shredder machine

Based on the purpose of use, shredders can be categorized as consumer shredders and industrial shredders. Thus, a paper shredder normally falls into the category of consumer shredder as it is mostly used by consumers. Industrial shredders are typically heavy-duty and high volume systems used to process such recycling material streams as e-waste, plastic,wood, and paper. Industrial shredders are equipped with different kinds of cutting systems such as vertical shaft design, horizontal shaft design, single shaft, two shaft, three shaft and four shaft cutting systems.

The use of the shredder in waste management and recycling

It has been realized that large quantity of waste remains being un-utilized and without being recycled because of handling, storage, transportation and management. In waste management, industrial shredders for waste products play a very crucial role. The benefits of using mega-shredders in large-scale waste disposal systems recycling centres and municipal landfills are related to material reduction. Asphalt, rubber, wood, plastics and similar materials can be quickly condensed to a mere fraction of their original size. Also, bio-degradable waste decomposes faster when shredded. If properly shredded, the materials that are buried in landfills take much less space.

In today’s economic environment, communities and businesses are always looking for new ways of cutting costs and use of shredders provides new strategic options. There are two main purposes of shredding materials in a recycling process. Firstly, by reducing the volume of material through reduction, transportation and storage costs may be decreased. Secondly, automated shredders, particularly in e-waste recycling, also liberate materials for recycling. Such equipment is offered by several vendors. Many options are available, depending upon the specific application.

There are different types of shredder machine, some are described below:-

Pedal Operated Shredder Machine

Fig pedal operated shredder machine

A pedal operated shredder machine mainly required two operators one for peddling, another one for feeding purpose.ie is the main disadvantage for this machine. In this concept, the bicycle mechanism for converting and transmitting human energy through paddling to rotational kinetic energy of flywheel is hereby proposed. The energy stored in the flywheel can then use for actual cutting process. This human energy output is in the low range and the processes could be operated intermittently can be considered for utilization.

Hand operated chaff cutter machine

The above figure shown is hand operated chaff cutter machine. Chaff cutters are meant for cutting all kinds of dry & green fodder into small pieces for cattle. These chaff cutters can chop the green or dry f Paddy, Grass, Groundnut etc. These machines are also useful for cutting, dry coconut leaves, Dairy Farms, and Jute Industries etc. where chopping is required. The advantages of the product are eco-friendly and maintenance is very easy.

Machine operated Shredder Machine

The currently available product for cutting of coconut leaves is as shown in figure 1.4. In the present model the outcome is in the stick form and later it must be crushed to obtain in powder form and the feeding of the coconut leaves in the existing model is of vertical type, which is difficult to feed the coconut leaves. It requires tractor PTO (Power take off shaft) machine cost also very expensive .To overcome from these problems the proposed model is developed.

OBJECTIVE

The objective of the current work is to make a low cost shredder machine. To fulfill the main objective of the work the following sub objectives are formed.

⦁ To design the components of organic waste shredder machine.

⦁ To manufacture a working model of the proposed design.

Components used:

The different components that have been used in the shredding machine are described below:-

- Cutting Blade

Single phase electric motor is used to generate power in the shredding machine which converts electric energy into mechanical energy. The specifications of electric motor are as follows:

Input Voltage 220 – 240 V, 60 Hz

Shaft is the component in which blades are mounted. When the electric motor generate torque, which when transmitted to the shaft the blades mounted on the shaft experience torque and rotate in desirable direction resulting the cutting action.

Belt drive is a mechanical drive which is used to transmit power from electric motor to the shaft where blades are mounted by driver and driven pulley. The ratio of driver and driven pulley is determined by the speed ratio between the speeds produced by the electric motor to the speed required to cut the organic waste.

Mesh Plate

It is a plate having desired holes in it. Its main function is to prevent the passing of larger size particles through it to get desirable sized output. The dimension of blade is shown in figure

Switch Board is used to start and stop the motor when required. It contains switch and indicator.

The method of designing the shredder machine start with gathering the information of necessity of the shredding machine and collecting the data from the literature review for development of specific mechanism. After collecting the information we made our effort to identify the mechanism and their roles in shredding machine to get the desired output.

Design Procedure

The basic procedure of the design consists of a step by step approach from specification about the functional requirement of the product to the complete description in the form of drawing of final product.

In order to reduce the cost of the shredding machine we have selected a simple mechanism. For example we have used a single shaft where number of blades are mounted and driven by an electric motor through belt drive system.

While selecting material we focused on the material that is easily available and also have strength compared to its cost. In case of cutting blades we have used mild steel and for belt drive, mineral-tanned leather is used as belt material. The design calculation of different components are explained below.

For vertical deflection,

RA + RB = 2397.85 N ……….eqn (11)

Taking equilibrium moment condition about A,

After successful fabrication of working model of shredder machine, performance is evaluated to determine the shredding efficiency of the machine. The cutting rate of the machine has been found out as 16.08kg/hr at an operational speed of 710rpm. Hence the shredding efficiency is found to be 57.26%.

0 Comments